Home / Requests / Explore

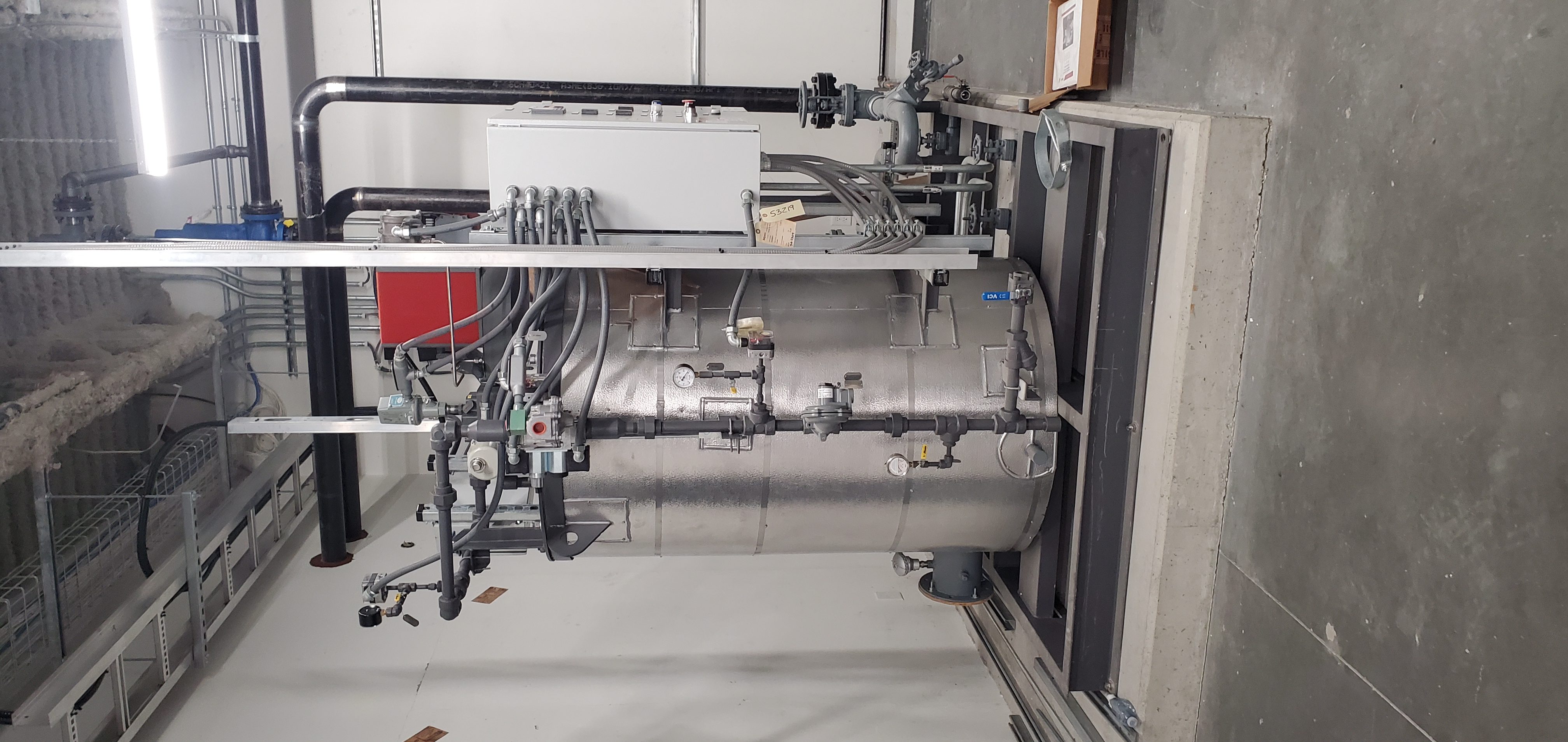

Deutsche Ethanol Extraction System

Equipment Overview

Equipment Category

Processing Equipment

Select Region

Canada

Model Number

N/A

Reference Price (Per Unit)

CAD $2,927,391.00

* The "Reference Price" is an indication of what the seller paid. This is not a "Buy Now" price. The Reference Price guides bidders to place offers below it in our marketplace, ensuring the winning bid remains lower than the listed reference price.

Date of Invoice

2021

Province

British Columbia

Quantity

1

Hours of Use

100-300

Description

ROTAX FLOW After extraction, the spent biomass is discharged from the Rotax vessel into our Desolventizing Drying Screw. This is a process of removing the residual solvent from your spent biomass through heat, motion and vacuum pressure. At scale, solvent gets expensive and easily drives operational costs. This skid is designed to recover solvent so it can be reused for further processing. This is the end of the lifeline for your biomass. From here we further refine your miscella into a crude oil and evaporate off ethanol from your oil. The next skid is our Oil Separation system which is a series of evaporators including a Rising Film Evaporator (RFE) that flows inline to a Wiped Film Evaporator (WFE). The RFE is set up to evaporate ~300 gallons/hour of ethanol from your oil and the WFE is more of a refinement evaporator to remove the last 5%-10% of etoh from your oil bringing you to the lowest ppm of etoh remaining. During this entire process, ethanol has been evaporated from many different points and that ethanol is being pumped to our Molecular Sieve skid which is an ethanol dehydration process. This skid is important for the longevity of your solvent and allows you to reuse ethanol by removing the residual moisture that is picked up during the extraction process. If your starting biomass has 10% moisture then that 10% would be picked up by your ethanol ultimately saturating your solvent with water and reducing the properties of that solvent for extraction purposes. The Mol-Sieve cleans up your ethanol and allows you to reuse it and keeps operational costs down.